Still have questions? Contact us!

Have a question?

We will be glad to answer!

We will be glad to answer!

By submitting an application, you consent to the processing of personal data and agree to the company's privacy policy.

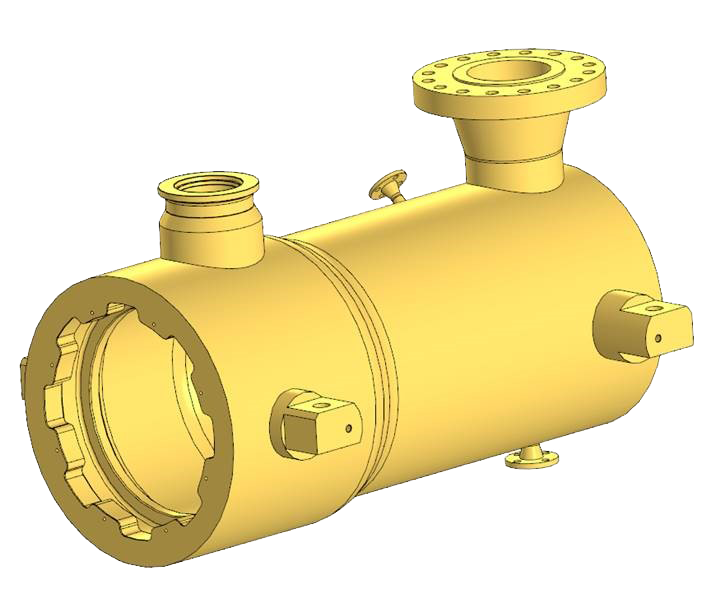

engineering solutions for rotating equipment

Integrated

Production and equipment maintenance for oil and gas, energy, and ore mining industry enterprises throughout Russia

By submitting an application, you consent to the processing of personal data and agree to the company's privacy policy.

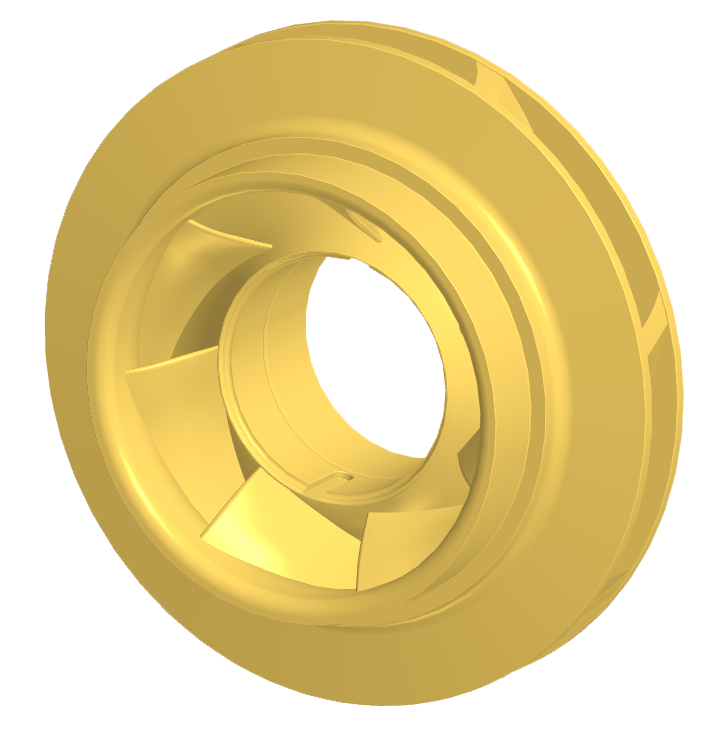

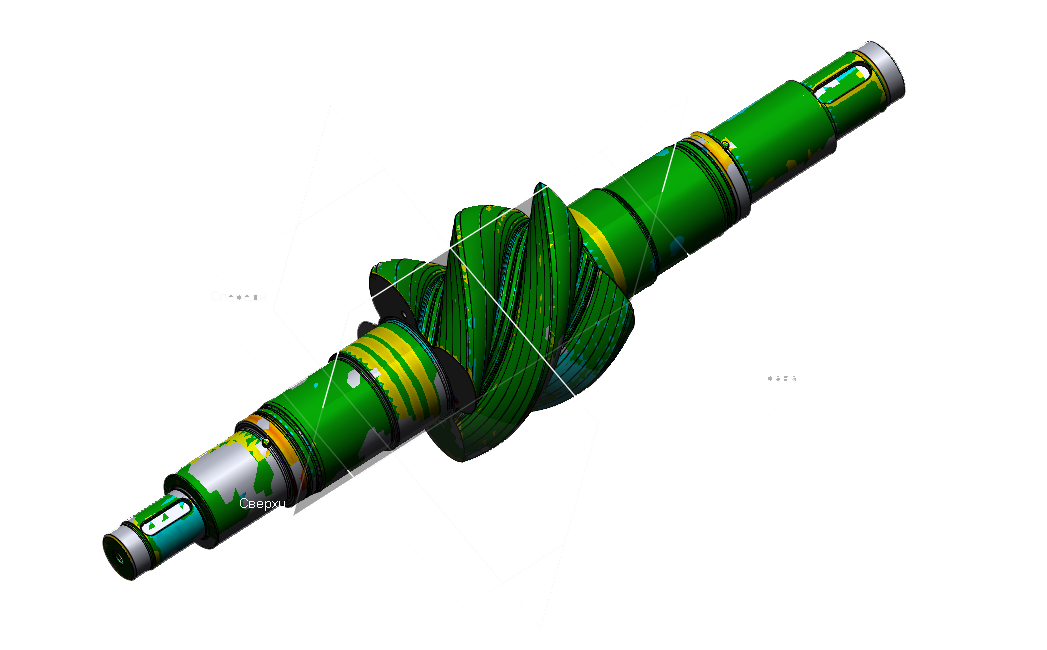

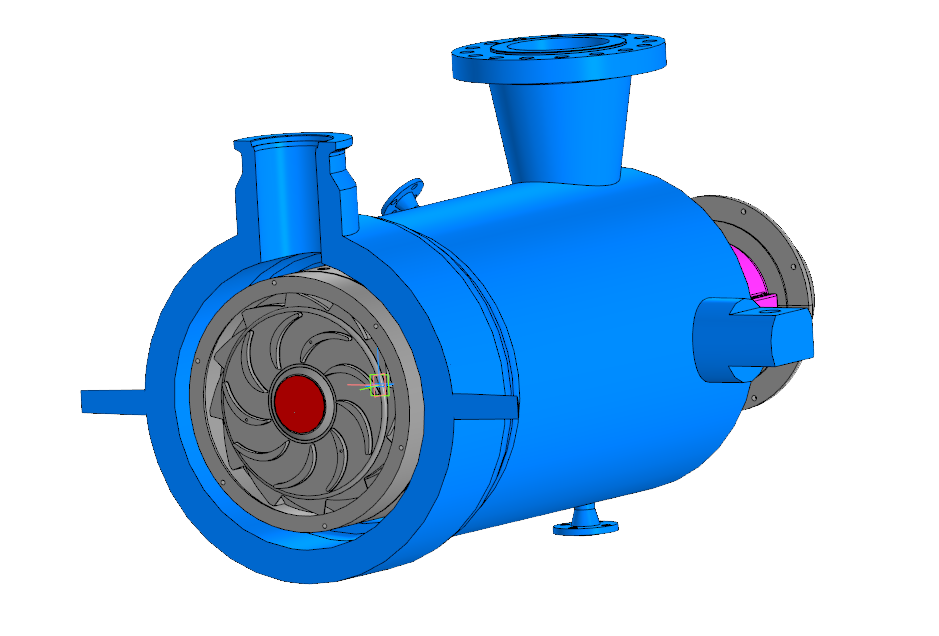

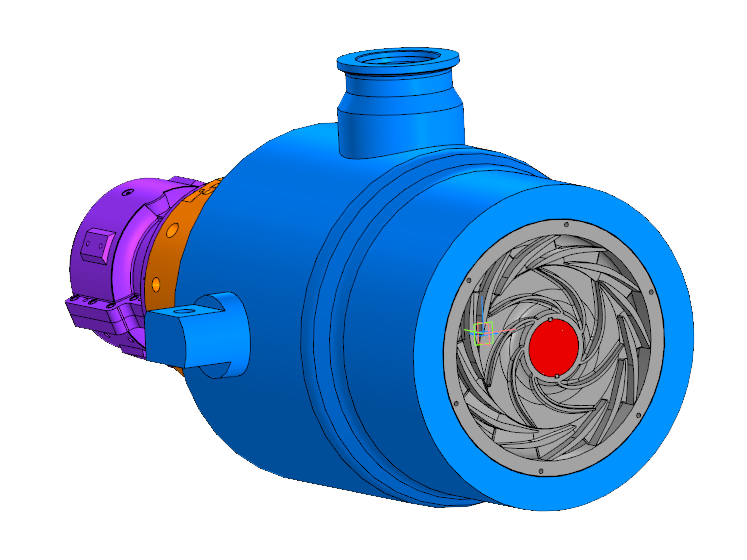

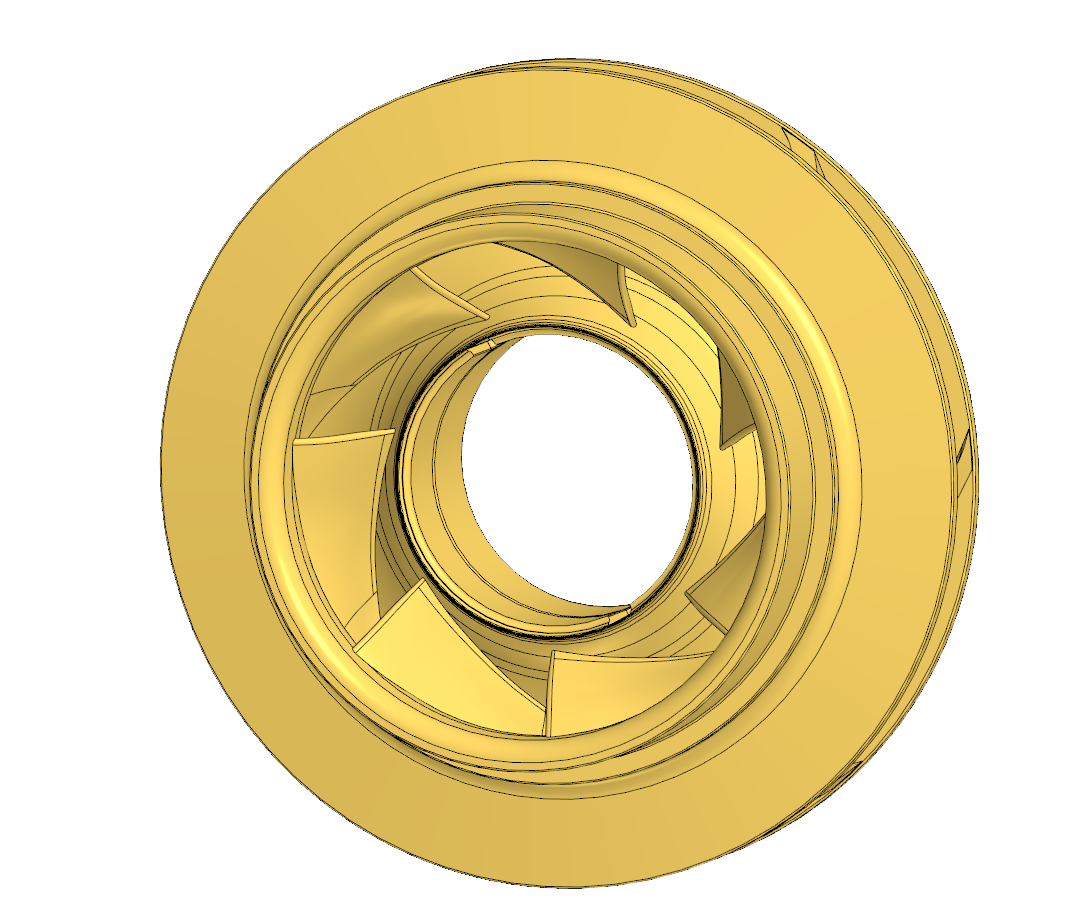

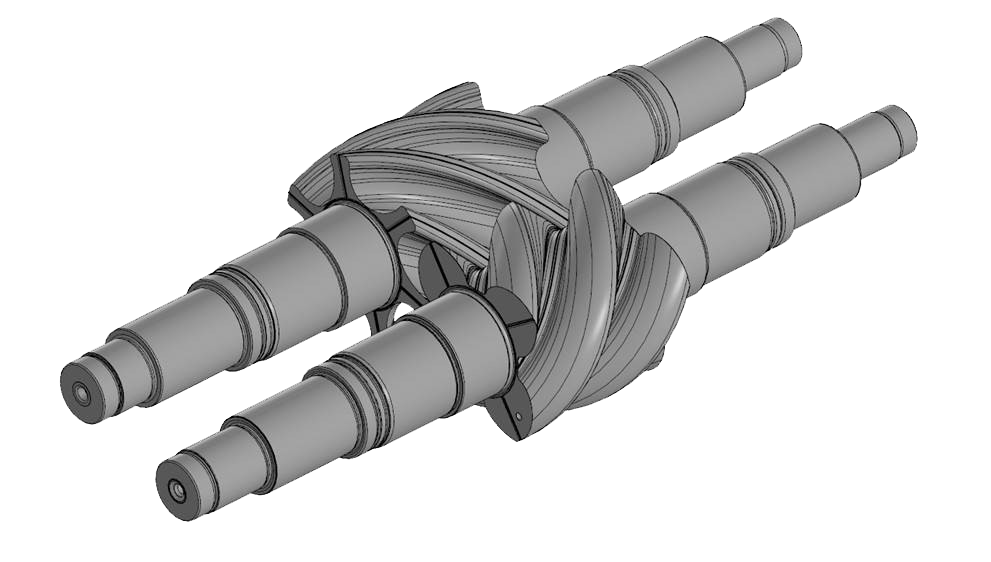

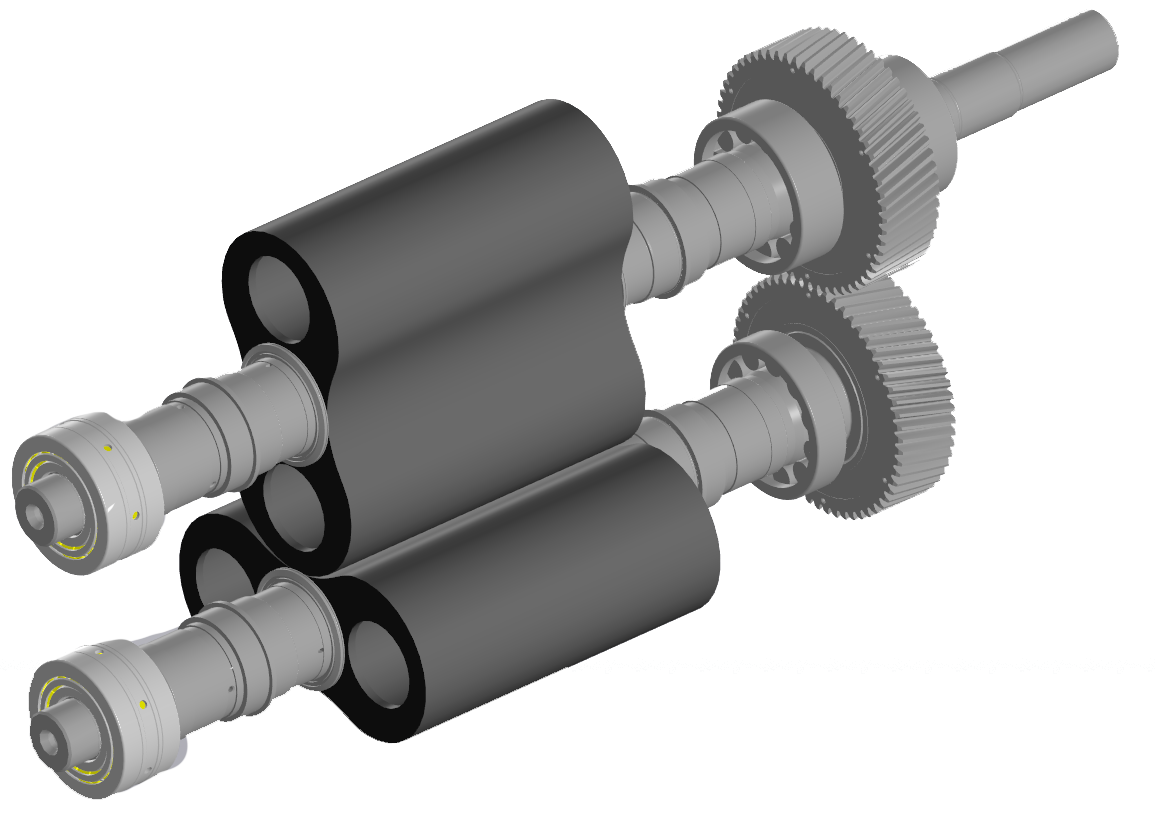

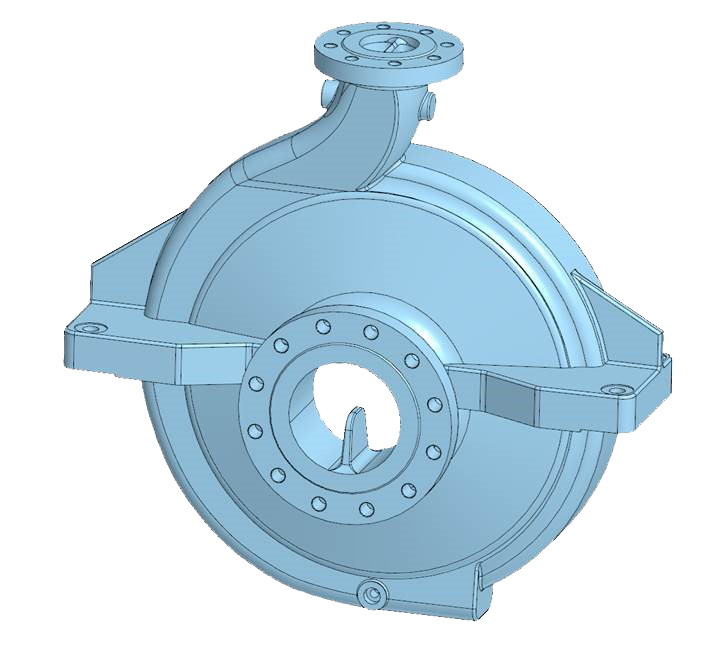

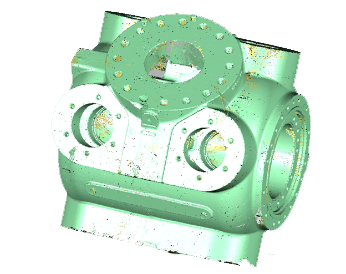

3D modeling of process complicated objects

Do you want to cooperate?

Our manager will contact you!

Our manager will contact you!

The company

We are the company ITR - Engineering and Technological Solutions. We believe that all kinds of tasks need to be solved comprehensively, for that reason we manufacture and supply spare parts of rotating equipment based on reverse engineering with the provision of a whole range of technical services.

9

9 years in the industry

since 2014 we have been solving technical tasks of any complexity

138

implemented

projects

projects

for manufacturing, repair and maintenance of rotating equipment

40

employees in production

engineering and technical specialties with work experience in foreign companies

77

units of equipment

produced in our production department

Certificates and licenses

The ITR company has all the necessary documentation for carrying out engineering and technical works:

- Certificate of compliance with GOST requirementsConfirmation of compliance with the requirements of GOST R ISO 9001-2015 (ISO 9001:2015)

- Certificate of compliance with GOST requirementsConfirmation of compliance with the requirements of GOST R ISO 14001-2016 (ISO 14001:2015)

- Certificate of membership in the Association of Compressor PlantsThe certificate was issued on 4.10.2022, by the Chairman of the Board of the Association B.A. Spector

- Extract from the register of members of a self-regulating organizationRegistration number SRO-S-287-15092017

Customer reviews and letters

For 9 years of work, we have received dozens of commendations for the quality of our work

- Gazpromneft-

Prirazlomnoye LLCRefurbishment and modernization of the pump. - Gazpromneft-

Shelf LLCEquipment overhaul - Gazpromneft-

Prirazlomnoye LLCOverhaul of the pump and multiplier.

We work according to individual technical solutions

- Own service center in Murmansk, Russia

Design Bureau and measuring laboratory in St. Petersburg, Russia.

- Cooperation with leading Russian machine-building enterprises and specialized technical universities.

- A large network of production partners in Russia and Asia.

Our advantages

We have a complete set of all the necessary resources and competencies to perform the most complex plug-and-produce tasks

- An integrated approachThe company implements complex projects ranging from preparatory measures, inspection and maintenance of equipment, repairs, measurements and engineering, and ending with the supply of spare parts, erection supervision and commissioning work.01

- Service CenterThe company has its own equipped service center in Murmansk. We are planning to open several service centers in various regions of Russia.02

- Supply of spare partsThe company produces and supplies spare parts of imported dynamic equipment based on reverse engineering, as well as the supply of original spare parts.03

- PartnersITR LLC has a large network of partners in Russia and Asia providing production services. Cooperation with leading Russian machine-building enterprises and specialized technical universities allows us to achieve a high-quality result of the work performed.04

- Own design department in St. PetersburgThe solution of complex technical problems is carried out by our own design department, formed of qualified specialists with significant experience in the development of components and elements of turbines and pump and compressor equipment, and also performing calculations.05

- Measuring equipmentThe company owns high–precise measuring equipment - 3D scanners and a hand-guided tool that allows you to obtain high-quality data on the geometry of parts, their material and index of hardness. The work is carried out by qualified engineers.06

- Service engineers teamExperienced qualified service engineers perform work of varying complexity from inspection to major repairs both in the conditions of the service center and at Customer’s area, including offshore production platforms.07

- Tools and equipmentThe Company owns all the necessary tools and equipment for carrying out repair and inspection work on the Customer's area both in the conditions of oil refining factories and petroleum chemical plants, and in the conditions of offshore production platforms.08

Are you interested in our activities?

Leave your data and our manager will contact you soon

Services

Everything from the production of spare parts using reverse engineering, to the repair and maintenance of rotating equipment

Deliveries

We supply spare parts of rotating equipment for the oil-gas, petrochemical and energy industries according to API, ANSI, ISO standards.

It is possible to supply both spare parts manufactured on the basis of the working construction documentation developed by our company as part of reverse engineering, and original spare parts.

It is possible to supply both spare parts manufactured on the basis of the working construction documentation developed by our company as part of reverse engineering, and original spare parts.

Compliance with production standards

Support for import substitution processes

Localization of global competencies

By delivering spare parts using reverse engineering, our specialists will make all the necessary measurements of parts. Design documentation will be developed and released. Parts will be manufactured and delivered according to this documentation. At the same time, it is possible to upgrade spare parts in order to improve the operational characteristics of the equipment.

All subsequent deliveries of spare parts by our forces will be carried out at no additional cost.

All subsequent deliveries of spare parts by our forces will be carried out at no additional cost.

ITR Technical Service develops comprehensive solutions for all customer needs.

The service department allows you to carry out maintenance and repair of equipment in our Murmansk service center and other service centers we are planning to open in the near future. Follow the information on the website.

In case of rendering services on the territory of the Customer, our service engineers will come to your company with all the necessary equipment and perform the required work efficiently.

The service department allows you to carry out maintenance and repair of equipment in our Murmansk service center and other service centers we are planning to open in the near future. Follow the information on the website.

In case of rendering services on the territory of the Customer, our service engineers will come to your company with all the necessary equipment and perform the required work efficiently.

Service

service is carried out in the service centre or on the customer's premises

Implementation of preventive measures to ensure smooth operation

Operational work within one or two working shifts

Highly qualified engineers take training courses in accordance with high standards to meet expert and technical requirements. They have all the necessary permits and approvals as well as many years of experience.

The technical service of ITR Company works under the guidance of the only certified specialist in Russia.HydroCom.

The technical service of ITR Company works under the guidance of the only certified specialist in Russia.HydroCom.

Technical audit

Conducting a technical audit (inspection) in our service centers or on the customer's premises allows:

Identify deviations in the operation of dynamic equipment and their causes

Identify sources of increased vibration of aggregates

Provide the Customer with an opinion on the condition of the equipment

Determine the amount of necessary maintenance and repair work

To form recommendations on the refinement / modernization of equipment in order to improve its operational characteristics

Repair or replacement of dynamic equipment components

Conducting detailed engineering of the project to improve performance parameters, economy, safety, etc.

Scanning the part in place

3D scanning of a part, photometry, sketching, instrumental measurement, analysis of material and hardness indicators

Creation

3D models

3D models

Building a three-dimensional model of a part based on the collected data

Geometry

control

control

Collection check, clearance control, work modeling, verification calculations

Release of drawings and manufacturing of parts

Release of working design documentation, support at all stages of production

Installation and commissioning

Installation of the part, assembly of the unit, control of the operation of the equipment with the supplied part

01

02

03

04

05

Implemented projects

We work with our clients on long-term service contracts that include all types of services and activities aimed at achieving our goals.

2020 year

Gazpromneft-

Prirazlomnoye LLC

Replacement of the pump cartridge with a new one from the Customer's warehouse.

Equipment: Sulzer HPcp 200-385-8s/27 Pump (BB5)

Gazpromneft-

Prirazlomnoye LLC

Replacement of the pump cartridge with a new one from the Customer's warehouse.

Equipment: Sulzer HPcp 200-385-8s/27 Pump (BB5)

2020 year

Gazpromneft-

Prirazlomnoye LLC

Refurbishment and modernization of the pump.Equipment: KSB HPK-EX 250-400 Pump (OH2)

Gazpromneft-

Prirazlomnoye LLC

Refurbishment and modernization of the pump.Equipment: KSB HPK-EX 250-400 Pump (OH2)

2020 year

Gazpromneft-

Prirazlomnoye LLC

Refurbishment and modernization of the pump. Equipment: KSB HPK-EX 250-400 Pump (OH2)

Gazpromneft-

Prirazlomnoye LLC

Refurbishment and modernization of the pump. Equipment: KSB HPK-EX 250-400 Pump (OH2)

2019 year

Gazpromneft-

Prirazlomnoye LLC

Disassembly, fault finding, reengineering and overhaul of the pump (item A). Production of spare parts and installation of new parts in the pump (position B), sending parts to the Customer's warehouse. The total volume of manufactured and delivered parts is 653 units.

Gazpromneft-

Prirazlomnoye LLC

Disassembly, fault finding, reengineering and overhaul of the pump (item A). Production of spare parts and installation of new parts in the pump (position B), sending parts to the Customer's warehouse. The total volume of manufactured and delivered parts is 653 units.

2019-2022 years

Gazpromneft-

Prirazlomnoye LLC

Rendering services for repair and maintenance service of pumping and compressor equipment MLSP "Prirazlomnaya" (184 units).

Equipment: Pumping, compressor units, Diesel drive stations.

Gazpromneft-

Prirazlomnoye LLC

Rendering services for repair and maintenance service of pumping and compressor equipment MLSP "Prirazlomnaya" (184 units).

Equipment: Pumping, compressor units, Diesel drive stations.

2019 year

Gazpromneft-

Shelf LLC

Heavy overhaul of gearboxes with replacement of spare parts.

Equipment: David Brown Type H1-180 gearbox (2 units)

Gazpromneft-

Shelf LLC

Heavy overhaul of gearboxes with replacement of spare parts.

Equipment: David Brown Type H1-180 gearbox (2 units)

2019 year

Gazpromneft-

Shelf LLC

Heavy overhaul of the gearbox with the modernization of the cooling system: replacement of the cooling coil.

Equipment: Gearbox Radicon H1-180

Gazpromneft-

Shelf LLC

Heavy overhaul of the gearbox with the modernization of the cooling system: replacement of the cooling coil.

Equipment: Gearbox Radicon H1-180

2019-2020 годы

Gazpromneft-

Prirazlomnoye LLC

Heavy overhaul of the pump. Reengineering and production of spare parts, heavy overhaul of the pump and installation of new parts.

Equipment: Sulzer HPcp 200-385-8s/27 Pump (BB5)

Gazpromneft-

Prirazlomnoye LLC

Heavy overhaul of the pump. Reengineering and production of spare parts, heavy overhaul of the pump and installation of new parts.

Equipment: Sulzer HPcp 200-385-8s/27 Pump (BB5)

2019 year

NMT LLC

Delivery of spare parts to Bornemann pumps total number of 112 units.

Equipment: Bornemann

NMT LLC

Delivery of spare parts to Bornemann pumps total number of 112 units.

Equipment: Bornemann

2019 year

NMT LLC

Delivery of spare parts to Bornemann pumps total number of 108 units including screw pair.

Equipment: Bornemann

NMT LLC

Delivery of spare parts to Bornemann pumps total number of 108 units including screw pair.

Equipment: Bornemann

2019 year

ZapSibNeftekhim LLC

Pump reengineering, production and delivery of spare parts. The total volume of 24 units including shafts, impellers, bearing parts, etc.

ZapSibNeftekhim LLC

Pump reengineering, production and delivery of spare parts. The total volume of 24 units including shafts, impellers, bearing parts, etc.

2019 year

NMT LLC

Delivery of spare parts to Bornemann pumps total number of 96 units.

Equipment: Bornemann

NMT LLC

Delivery of spare parts to Bornemann pumps total number of 96 units.

Equipment: Bornemann

2020 year

Gazpromneft-

Prirazlomnoye LLC

Production and delivery of the shaft to the pump, L= 3385 mm. D= 38 mm.

Equipment: Liquefied Ammonia pump manufactured by Shin Nippon Machinery

Gazpromneft-

Prirazlomnoye LLC

Production and delivery of the shaft to the pump, L= 3385 mm. D= 38 mm.

Equipment: Liquefied Ammonia pump manufactured by Shin Nippon Machinery

2021 year

Gazpromneft-

Prirazlomnoye LLC

Disassembly, defection and reengineering of the pump.Heavy overhaul of the pump.

Equipment: Pump SD125-6 DUHH90-A320 made by Frank Mohn (Framo)

Gazpromneft-

Prirazlomnoye LLC

Disassembly, defection and reengineering of the pump.Heavy overhaul of the pump.

Equipment: Pump SD125-6 DUHH90-A320 made by Frank Mohn (Framo)

2021 year

JSC "TAIF-NK"

Reengineering and production of two upgraded pump enclosure and two impellers.

Equipment: Flowserve 4 HPX 25 SL Pump

JSC "TAIF-NK"

Reengineering and production of two upgraded pump enclosure and two impellers.

Equipment: Flowserve 4 HPX 25 SL Pump

2020 year

Gazpromneft-

Prirazlomnoye LLC

Disassembly, defection, reengineering and heavy overhaul of the pump with production.

Spare parts and installation of new parts in the pump, sending parts to the Customer's warehouse.

The total volume of manufactured and delivered parts is 1214 units.

Gazpromneft-

Prirazlomnoye LLC

Disassembly, defection, reengineering and heavy overhaul of the pump with production.

Spare parts and installation of new parts in the pump, sending parts to the Customer's warehouse.

The total volume of manufactured and delivered parts is 1214 units.

2021 year

Gazpromneft-

Prirazlomnoye LLC

Heavy overhaul of the pump cartridge with replacement of spare parts (produced by ITR LLC): 1. Shaft 2. Ring lining 3. Cylindrical pin (5 units) 4. Flat-end mounting screw (60 units) Surfacing and repair of impellers.

Gazpromneft-

Prirazlomnoye LLC

Heavy overhaul of the pump cartridge with replacement of spare parts (produced by ITR LLC): 1. Shaft 2. Ring lining 3. Cylindrical pin (5 units) 4. Flat-end mounting screw (60 units) Surfacing and repair of impellers.

2021 year

Gazpromneft-

Prirazlomnoye LLC

Heavy overhaul of the pump and multiplier.

Equipment: Sulzer HPcp 150-275-26 pump + David Multiplier

Brown 315 CRS H.S.S.I.G

Gazpromneft-

Prirazlomnoye LLC

Heavy overhaul of the pump and multiplier.

Equipment: Sulzer HPcp 150-275-26 pump + David Multiplier

Brown 315 CRS H.S.S.I.G

2020 year

Gazpromneft-

Prirazlomnoye LLC

Replacement of the pump cartridge with a new one from the Customer's warehouse.

Equipment: Sulzer HPcp 200-385-8s/27 Pump (BB5)

Gazpromneft-

Prirazlomnoye LLC

Replacement of the pump cartridge with a new one from the Customer's warehouse.

Equipment: Sulzer HPcp 200-385-8s/27 Pump (BB5)

2020 year

Gazpromneft-

Prirazlomnoye LLC

Development of the working construction documentation, production and supply of an analog pump to replace the existing pump.

Equipment: Sulzer ZE 150-2-200 Pump

Gazpromneft-

Prirazlomnoye LLC

Development of the working construction documentation, production and supply of an analog pump to replace the existing pump.

Equipment: Sulzer ZE 150-2-200 Pump

Do you want to cooperate?

Leave your data and our manager will contact you!

By submitting an application, you consent to the processing of personal data and agree to the company's privacy policy.

Office of the company "Engineering and technological solutions" LLC

St. Petersburg,

Krasnogvardeyskaya square, 3 liter E

info@i-t-r.net

+7 (812) 407-12-84